Why JMP: Our Purpose

The reason we exist, our purpose, is to enable people and businesses to reach their full potential by helping them continually redefine what is possible. By redefining, we don’t necessarily mean reinventing, rather we seek to engage, perform and communicate in creative and thoughtful ways that others may not consider, delivering an experience unlike any other; one that is uniquely JMP. This purpose extends far beyond our walls, including not only our customers, partners and employees but to each and every stakeholder that we interact with throughout industry and our communities both personally and professionally.

The JMP Promise

We hold true to our values and the tenet that our word is our bond. We actively live this philosophy daily across every aspect of our organization. We are a company based on values and beliefs, crafted into a process that results in the solutions we develop for our customers. Our promise is the ideal through which we hold ourselves accountable to our customers and partners, ensuring satisfaction and excellence through unwavering professionalism and quality leadership. The foundation of our promise of an extraordinary customer experience is anchored in three central principles by which we measure ourselves and reflect on each and every day:

- Guarantee Performance

- Radical Commitment

- Exceptional Communication

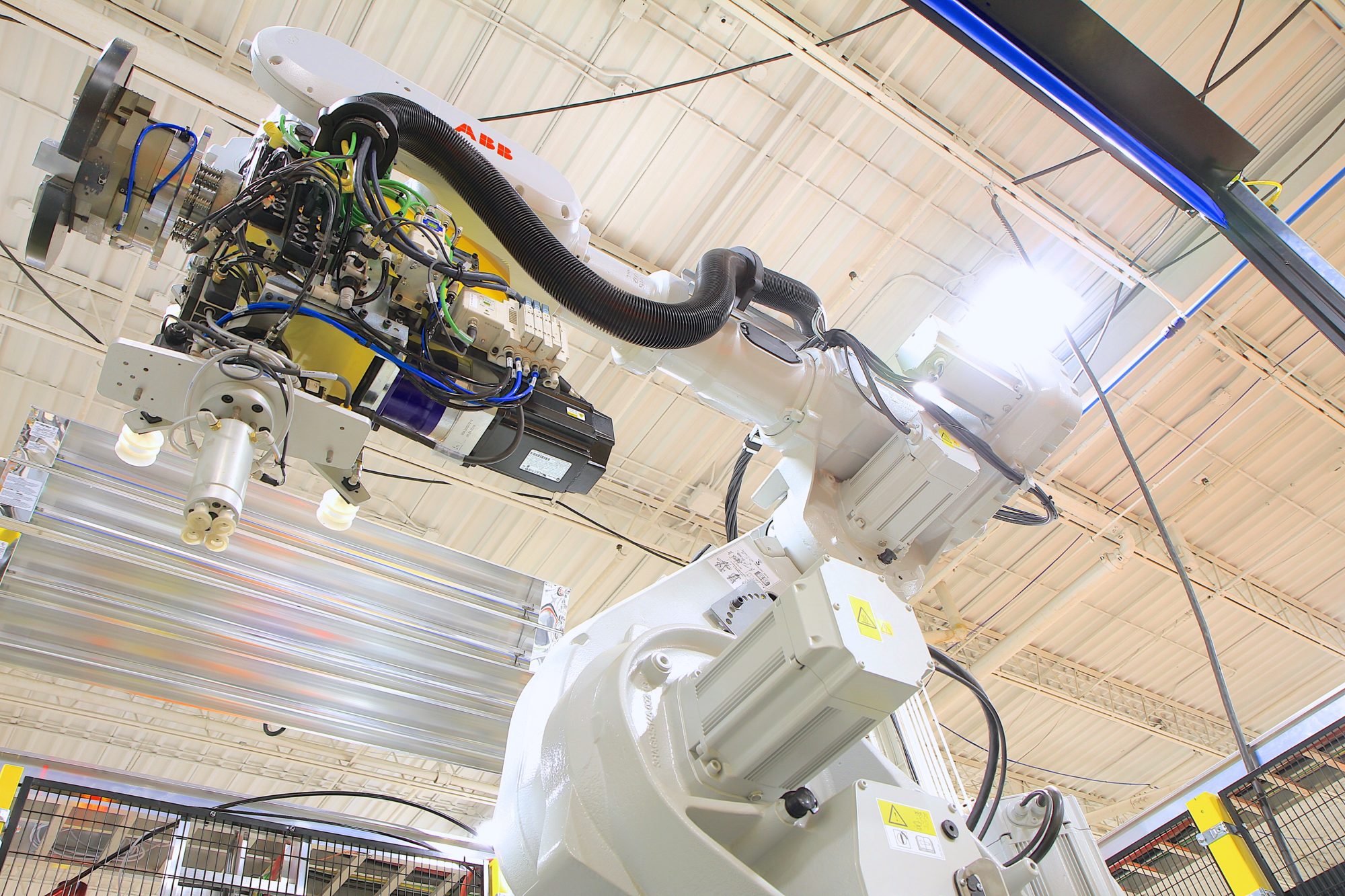

What We Do

We design, create and bring to reality innovative automation solutions that enable our partners to better serve their clients and customers, thereby differentiating themselves in their market while providing a safer and more effective workplace for their employees. Our product is at its core, a collaborative mosaic of ideas borne out of our hands-on, customer centric process in which our partners and customers play an integral role. While our systems and solutions are the tangible representation of what we offer, we believe that these are simply a component of the greater JMP offering; extending well beyond the physical product that we deliver.

Our six unique divisions allow us to provide innovative cross-disciplinary solutions expertly encompassing your entire operations.

- Process Automation

- Control System Integration

- Information Systems

- Automation & Robotics

- Automated Guided Vehicles

- Networking & Security